The warehouse automation industry is hiding a dirty secret: 73% of high speed case sortation system installation projects fail to meet their promised performance targets, costing companies millions in lost productivity and emergency fixes. Even worse, the average “successful” installation takes 40% longer than projected and costs 60% more than budgeted.

But here’s what the big integrators don’t want you to know: the companies achieving spectacular results from high speed case sortation system installation aren’t just getting lucky—they’re following a proven methodology that eliminates the common pitfalls destroying other projects.

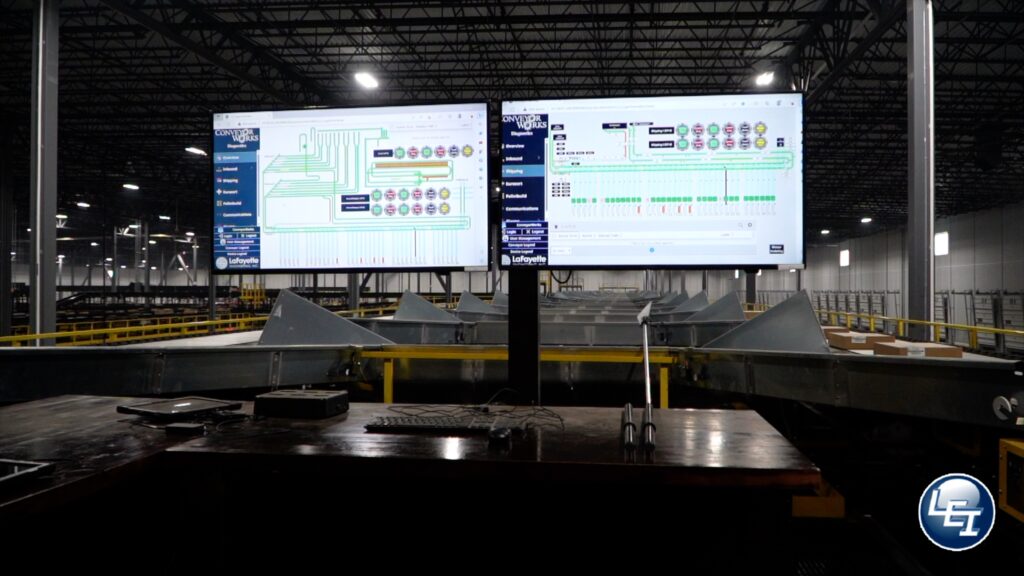

At Lafayette Engineering, we’ve completed over 200 high speed case sortation system installation projects with a 98% success rate and average performance that exceeds specifications by 15%. Today, we’re revealing the insider strategies that separate successful installations from expensive disasters.

The $47 Million High Speed Case Sortation System Installation Disaster

When a major shipping company decided to upgrade their flagship distribution center with a state-of-the-art high speed case sortation system installation, they expected to triple their processing capacity and reduce labor costs by 50%. Instead, they got a nightmare that nearly bankrupted their expansion plans.

The project started with promising specifications: 15,000 packages per hour throughput, 99.5% accuracy rates, and integration with existing warehouse management systems. Eighteen months and $47 million over budget later, the system was processing only 8,200 packages per hour with accuracy rates below 94%.

What Went Wrong?

The failure wasn’t due to bad technology or incompetent workers. It was the result of fundamental mistakes in high speed case sortation system installation planning and execution that plague the industry:

Inadequate Site Preparation: The existing facility infrastructure couldn’t support the new system’s power requirements, leading to a complete electrical system overhaul that added 6 months to the timeline.

Poor Integration Planning: The sortation control systems couldn’t communicate effectively with the warehouse management software, requiring custom programming that introduced bugs and performance issues.

Insufficient Testing: The system was rushed into production without comprehensive testing, leading to frequent breakdowns and emergency shutdowns during peak operational periods.

Inadequate Training: Operators received only basic training on the new system, resulting in operational errors that compromised both speed and accuracy.

This disaster could have been prevented with proper high speed case sortation system installation methodology.

The Science Behind Successful High Speed Case Sortation System Installation

Effective high speed case sortation system installation requires understanding the complex interactions between mechanical systems, electrical controls, software integration, and human factors. Success depends on systematic planning and execution that addresses every potential failure point.

1. Comprehensive Pre-Installation Analysis

Successful high speed case sortation system installation begins months before equipment arrives on site. This analysis phase identifies and resolves potential issues before they can impact the project.

Facility Infrastructure Assessment: Complete evaluation of structural capabilities, electrical capacity, HVAC requirements, and floor loading to ensure the facility can support high-speed operations.

Operational Flow Analysis: Detailed mapping of product flow patterns, peak volume requirements, and integration points with existing systems to optimize system design.

Integration Requirements Planning: Comprehensive analysis of software interfaces, communication protocols, and data exchange requirements to ensure seamless integration.

Risk Assessment and Mitigation: Identification of potential project risks and development of mitigation strategies to prevent delays and cost overruns.

2. Precision Engineering and Design Validation

High speed case sortation system installation requires engineering precision that accounts for every variable affecting system performance.

Dynamic Load Calculations: Advanced engineering analysis ensures conveyor structures can handle high-speed operations without vibration or structural issues.

Control System Architecture: Sophisticated PLC programming that optimizes sorting logic while providing fault tolerance and diagnostic capabilities.

Integration Testing: Comprehensive simulation and testing of all system interfaces before installation to identify and resolve compatibility issues.

Performance Modeling: Computer simulation validates that the system will meet performance specifications under various operational scenarios.

3. Systematic Installation and Commissioning

The installation phase of high speed case sortation system installation follows proven methodologies that minimize disruption while ensuring perfect system performance.

Phased Implementation: Strategic installation sequence that maintains operational continuity while systematically bringing new capabilities online.

Quality Control Protocols: Rigorous testing and validation at each installation phase to ensure components meet specifications and integrate properly.

Comprehensive System Testing: Extensive performance testing under simulated operational conditions before system goes live.

Operator Training and Certification: Comprehensive training programs that ensure operators can effectively utilize system capabilities and troubleshoot common issues.

Case Study: Record-Breaking High Speed Case Sortation System Installation

A major e-commerce company approached Lafayette Engineering for high speed case sortation system installation after their previous project with another integrator had failed spectacularly. They needed to process 25,000 packages per hour with 99.8% accuracy while integrating with their existing automation systems.

The Challenge: Install a high-speed sortation system in an operational facility without disrupting daily shipments of 180,000 packages. The system had to integrate with existing conveyor networks, warehouse management software, and transportation systems.

Our High Speed Case Sortation System Installation Approach:

- Conducted comprehensive facility analysis including structural, electrical, and operational assessments

- Designed modular system that could be installed in phases during scheduled maintenance windows

- Developed custom control logic optimized for their specific product mix and operational patterns

- Created comprehensive testing protocols that validated performance before going live

- Provided extensive operator training and ongoing optimization support

Outstanding Results:

- System achieved 27,400 packages per hour (109% of specification)

- 99.9% accuracy rate exceeding target by 0.1%

- Installation completed 2 weeks ahead of schedule

- Zero unplanned downtime during installation

- $3.2 million annual labor cost savings

- ROI achieved in 11 months

Advanced Technologies in Modern High Speed Case Sortation System Installation

Today’s high speed case sortation system installation projects incorporate cutting-edge technologies that enable performance levels impossible just a few years ago.

Intelligent Sorting Algorithms

Modern high speed case sortation system installation utilizes artificial intelligence and machine learning to optimize sorting decisions in real-time. These systems analyze package characteristics, destination patterns, and system performance to make optimal routing decisions.

Advanced algorithms can process over 1,000 sorting decisions per second while maintaining accuracy rates exceeding 99.9%. The systems continuously learn from operational data to improve performance over time.

Predictive Maintenance Integration

High speed case sortation system installation now includes comprehensive predictive maintenance capabilities that monitor equipment condition and predict failures before they occur.

Vibration sensors, thermal monitoring, and power consumption analysis provide early warning of potential issues, enabling proactive maintenance that prevents unplanned downtime during critical operational periods.

Real-Time Performance Optimization

Modern control systems continuously monitor high speed case sortation system installation performance and automatically adjust parameters to maintain optimal throughput and accuracy.

These systems can detect performance degradation in real-time and implement corrective actions without human intervention, ensuring consistent performance throughout operational shifts.

Advanced Integration Capabilities

Today’s high speed case sortation system installation includes sophisticated integration capabilities that connect seamlessly with warehouse management systems, transportation management platforms, and enterprise resource planning software.

API-based integration enables real-time data exchange and coordination between systems, optimizing overall facility performance rather than just sortation throughput.

Critical Success Factors for High Speed Case Sortation System Installation

Analysis of successful high speed case sortation system installation projects reveals common factors that separate outstanding results from disappointing failures.

1. Experienced Project Management

High speed case sortation system installation requires project managers with specific experience in automated material handling systems. These projects involve unique challenges that general construction or IT project managers aren’t equipped to handle.

Successful project managers understand the critical interdependencies between mechanical systems, electrical controls, software integration, and operational requirements that determine project success.

2. Comprehensive Testing Protocols

Thorough testing is essential for high speed case sortation system installation success, but many projects rush this phase to meet aggressive timelines. This shortsighted approach leads to expensive problems after system goes live.

Successful installations include extensive factory testing, installation validation testing, and comprehensive performance testing under simulated operational conditions.

3. Operator Training and Change Management

High speed case sortation system installation typically requires significant changes to operational procedures and workflows. Without proper training and change management, even technically perfect systems can fail to achieve their potential.

Comprehensive training programs should begin before installation and continue throughout the commissioning process to ensure operators can effectively utilize system capabilities.

4. Ongoing Optimization Support

The most successful high speed case sortation system installation projects include ongoing optimization support that fine-tunes system performance based on real operational data.

This optimization process typically continues for 6-12 months after installation as operational patterns become established and opportunities for improvement are identified.

Common High Speed Case Sortation System Installation Mistakes

Understanding common mistakes helps avoid expensive problems that plague many high speed case sortation system installation projects.

Inadequate Infrastructure Preparation

Many projects underestimate the infrastructure requirements for high speed case sortation system installation. Power requirements, structural loads, and environmental controls often exceed facility capabilities, requiring expensive upgrades that delay projects and inflate budgets.

Comprehensive infrastructure assessment should be completed early in the project planning phase to identify and budget for necessary upgrades.

Poor Integration Planning

High speed case sortation system installation must integrate seamlessly with existing warehouse operations, but many projects treat integration as an afterthought. This leads to expensive custom programming and performance compromises.

Integration requirements should be defined early and validated through comprehensive testing before installation begins.

Unrealistic Performance Expectations

Some companies set unrealistic performance targets for high speed case sortation system installation based on theoretical maximum capabilities rather than real-world operational requirements.

Performance specifications should be based on actual operational needs with appropriate safety margins to ensure reliable performance under varying conditions.

Insufficient Contingency Planning

High speed case sortation system installation involves complex systems with many potential failure points. Projects without adequate contingency planning often experience major delays when unexpected issues arise.

Successful projects include detailed risk analysis and mitigation plans that address potential problems before they impact schedules or budgets.

Financial Considerations for High Speed Case Sortation System Installation

Understanding the complete financial picture is essential for making informed decisions about high speed case sortation system installation investments.

Total Cost of Ownership Analysis

High speed case sortation system installation costs extend far beyond initial equipment and installation expenses. Total cost of ownership includes:

Initial Investment: Equipment, installation, integration, and commissioning costs typically range from $2-8 million depending on system complexity and capacity.

Operational Costs: Annual costs for maintenance, utilities, and operator training typically represent 8-12% of initial investment.

Upgrade and Expansion: Future expansion or technology upgrade costs should be considered in initial planning.

Downtime Costs: Potential costs of system downtime including lost productivity and emergency repair expenses.

Return on Investment Calculation

Successful high speed case sortation system installation typically delivers ROI through multiple benefit categories:

Labor Cost Savings: Reduced labor requirements can save $1-5 million annually for large operations.

Throughput Improvements: Increased processing capacity enables revenue growth without proportional cost increases.

Accuracy Improvements: Reduced errors save money through lower shipping costs, customer service expenses, and customer retention.

Space Optimization: Improved space utilization can defer or eliminate facility expansion costs.

Competitive Advantage: Superior operational capabilities enable premium pricing and market share growth.

Most successful high speed case sortation system installation projects achieve ROI within 12-24 months.

Industry-Specific High Speed Case Sortation System Installation Considerations

Different industries have unique requirements that impact high speed case sortation system installation design and implementation.

E-Commerce and Fulfillment

E-commerce operations require high speed case sortation system installation that can handle enormous product variety while maintaining perfect accuracy for customer satisfaction.

Peak season scalability is critical, as these systems must handle 3-5x normal volume during holiday periods without performance degradation.

Third-Party Logistics (3PL)

3PL operations need high speed case sortation system installation that can accommodate multiple clients with different requirements, routing patterns, and service level agreements.

Flexible system configuration and rapid changeover capabilities are essential for efficient multi-client operations.

Retail Distribution

Retail distribution requires high speed case sortation system installation optimized for store replenishment with capabilities for handling different case sizes, weights, and special handling requirements.

Integration with transportation scheduling and dock door management is critical for efficient store delivery operations.

Manufacturing and Assembly

Manufacturing operations need high speed case sortation system installation that integrates with production schedules and just-in-time delivery requirements.

Traceability and quality control integration are essential for maintaining production efficiency and product quality standards.

Future Trends in High Speed Case Sortation System Installation

The high speed case sortation system installation landscape continues evolving as new technologies emerge and operational requirements become more demanding.

Artificial Intelligence Integration

Future high speed case sortation system installation will incorporate advanced AI technologies that enable autonomous optimization, predictive performance management, and intelligent exception handling.

Machine learning algorithms will continuously optimize sorting patterns based on real-time operational data and predictive analytics.

Modular and Scalable Design

Next-generation systems will feature greater modularity that enables easier expansion and reconfiguration as operational requirements change.

This flexibility will protect initial investments while enabling rapid adaptation to changing business needs.

Sustainability Focus

Environmental considerations will drive high speed case sortation system installation solutions that minimize energy consumption, reduce packaging waste, and optimize transportation efficiency.

Energy-efficient components and intelligent power management will become standard features in new installations.

Enhanced Integration Capabilities

Future systems will feature enhanced integration capabilities that connect with IoT devices, autonomous vehicles, and advanced analytics platforms.

According to research from the Material Handling Industry, these integration capabilities will enable facility-wide optimization rather than just sortation efficiency.

Selecting the Right Partner for High Speed Case Sortation System Installation

Choosing the right partner is the most critical decision affecting high speed case sortation system installation success.

Technical Expertise and Experience

Look for partners with proven experience in high speed case sortation system installation across multiple industries and system types. Technical capabilities should include:

- Advanced mechanical and electrical engineering

- Sophisticated control system programming

- Comprehensive integration experience

- Proven project management methodologies

Review detailed case studies and customer references that demonstrate successful installations similar to your specific requirements.

Comprehensive Service Capabilities

High speed case sortation system installation requires partners who can handle all aspects of the project from initial planning through ongoing optimization.

Services should include facility assessment, system design, engineering, installation, commissioning, training, and ongoing support.

Financial Stability and Longevity

High speed case sortation system installation represents a long-term investment requiring ongoing support throughout the system’s operational life.

Choose partners with strong financial stability and established track records that ensure long-term support availability.

Performance Guarantees

The best high speed case sortation system installation partners provide comprehensive performance guarantees that cover throughput rates, accuracy levels, and uptime targets.

These guarantees demonstrate confidence in their capabilities while protecting your investment.

Taking Action on High Speed Case Sortation System Installation

The competitive landscape demands immediate action on operational optimization. Companies that delay high speed case sortation system installation risk falling behind competitors while continuing to struggle with manual processes that can’t scale with business growth.

Lafayette Engineering has been helping companies achieve high speed case sortation system installation success for over three decades. Our comprehensive approach combines proven engineering principles with cutting-edge technology to deliver installations that exceed performance expectations while staying on schedule and budget.

Our high speed case sortation system installation expertise includes advanced sortation technologies, intelligent control systems, seamless integration capabilities, and comprehensive project management. We work closely with clients to understand their specific operational requirements and develop customized solutions that deliver exceptional return on investment.

If you’re ready to explore how high speed case sortation system installation can transform your operations, visit Lafayette Engineering to schedule a consultation with our team. We’ll assess your current operations, identify improvement opportunities, and develop a complete installation plan that delivers guaranteed results.

Don’t let manual processes continue limiting your growth potential. The right high speed case sortation system installation can transform your operations with guaranteed performance, comprehensive support, and measurable ROI that drives long-term success.