Lafayette Engineering is pleased to announce an East Coast Success Story. In early 2021, Lafayette Engineering was approached by an upcoming industry leader with the request of providing a new system for meet their expanding east coast growth. A facility capable of processing 260K cartons per day, including cartons and Polybags.

LMS Magnetic Divert Switch: East Coast Success

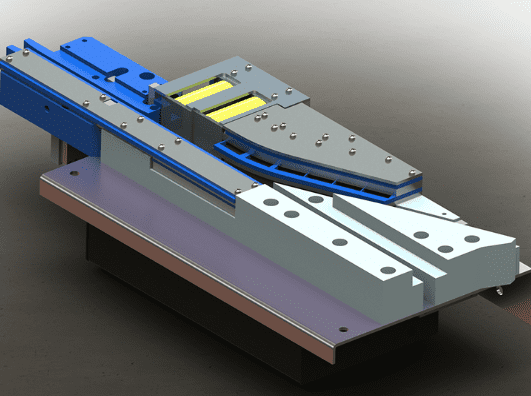

We designed and fulfilled this request. We partnered with Eurosort for Polybags and Hytrol Conveyor for Cartons. Together with our partners, we implemented and created a seamless flow of products from receiving, capturing weights, dimensions, and barcodes, to outbound destinations. We implemented our LMS Magnetic Divert Switch allowing faster response speeds on the Outbound Sorters.

Our ConveyorWorks software team worked with the customer’s WMS to provide a custom solution supporting their on-demand technology requirements to track each package and ensuring that each Carton and Polybag successfully reaching the correct outbound destination, ensuring an on-time delivery to their customers.

In an amazing feat, this facility opened in time for peak season and boasted an output of 266K cartons per day within the first month of becoming fully operational. Since then, this facility has continued to achieve record production numbers, surpassing the original goals and expectations. We are honored to continue and cultivate growth with this customer and assist with them additional facilities across the U.S.