In the materials handling industry, we see a lot of products. From large boxes to small bagged items, we generally have figured out efficient methods to get most materials from Point A to Point B. But, as you’re likely aware, some items don’t play nicely with your standard conveyor system. These items, categorized as “non-conveyables”, are processed separately and often sorted manually.

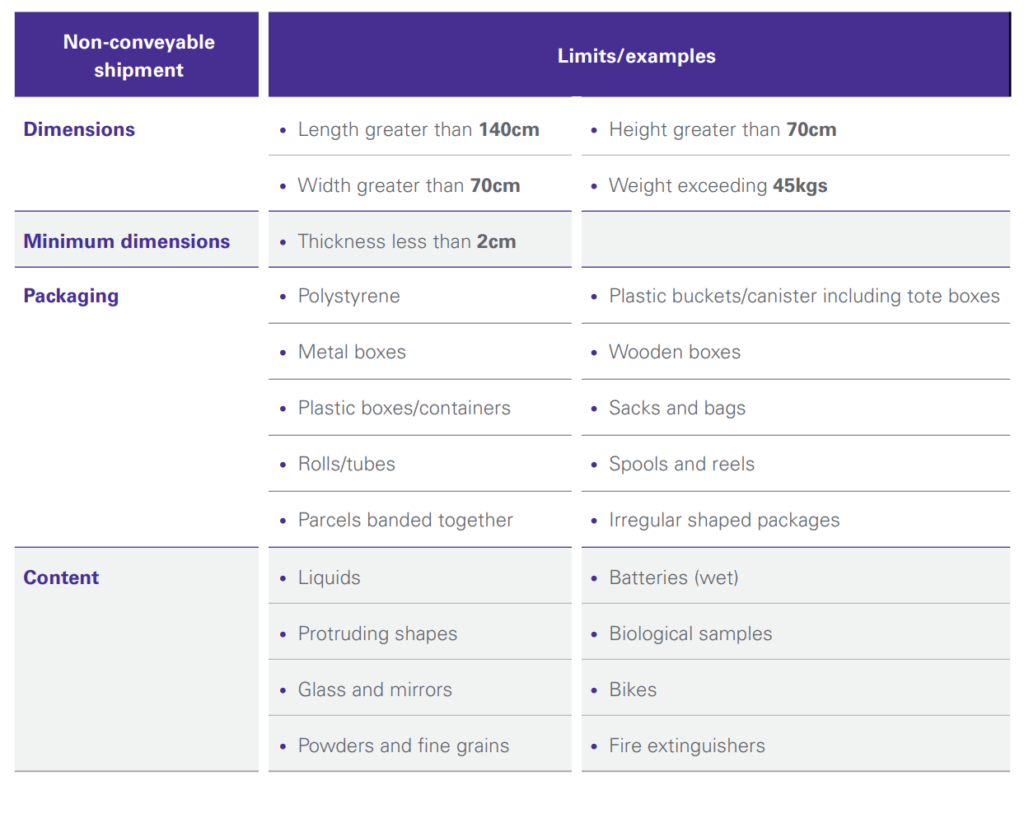

Here’s how FedEx defines a non-conveyable:

“A shipment is classed as non-conveyable if it cannot be sorted on our automated machinery. Items can be deemed as non-conveyable due to their weight, size, packaging, contents or the potential to cause damage.”

These items can be too small for photo eyes to detect, too heavy to move across conveyors, or just too irregularly shaped to fit into a conveyor. The conundrum is that we simply can’t standardize everything. We create conveyor systems to handle the vast majority of products, but we simply cannot accommodate every size or shape at this point. Because of this, there really is no blueprint for how to manage non-conveyables, and they can create a logistical nightmare.

And, since non-conveyable items must be sorted manually, they can really slow down an otherwise fast-flowing operation. Manual sorting decreases productivity, requires dedicated labor, reduces the level of traceability, and often poses a higher risk for error.

So how should you manage non-conveyables?

Automation

First, it’s important to consider if automation is a possibility in some capacity.

Can you simply move the parcel to another location in your facility that can accomodate? Perhaps a wider conveyor would solve the problem? Unfortunately, the more irregular a parcel is, the less likely it is that you will be able to use an automated system to move it.

That being said, one of the most effective ways to handle non conveyable items is with specialized equipment. Specialized equipment is very helpful because it provides pre engineered take-away options that standard automation doesn’t provide. This equipment can significantly reduce manual effort, keep productivity consistent, and give you a bang for your buck.

Specialized equipment is extremely useful for facilities who handle a large number of non-conveyable items. If your facility deals with this often, investing in specialized equipment is a great way to speed up your processes and the investment pays off immensely in the long run.

There is also room for partial automation in using a system to detect the weight and volume of the parcel.

Human Intervention

Next, you’ll need to determine how much human intervention is needed. Expecting an automated system to handle every irregular item on its own is unrealistic for many facilities.

Many items require some form of human assistance in order to flow smoothly through a warehouse, whether that’s physically moving the parcel to another side of the facility, workers packaging by hand, or an engineer manually controlling processes.

The reality is, most automated systems just simply are not designed to handle irregular items, and we have to fill in those holes, somehow. Human intervention can be used to fill in the gaps that conveyors and other forms of automation simply cannot. When you cannot rely on your automated systems, the most important question to ask is, “how can we make it work as efficiently as possible?”

Transport

Here’s where managing non-conveyables gets a little tricky: transport logistics. Transporting non-conveyables will require much more coordination and deliberation than regular parcels.

For example, smaller non-conveyable items, though irregular, may still end up packaged and on the way to a distribution facility. In contrast, larger items like appliances would be better suited to transport directly in trucks. Depending on how many non-conveyables flow through your facility, it can become quite the juggling act to balance average system intervals along with the extra assistance an irregular item can incur. If you’re not careful, transport logistics for your non-conveyable items can really drive up costs.

Because shipment of non-conveyables requires a more hands-on approach, we recommend that you implement any necessary steps that will make manual processes more efficient. This can be special handling labels, ‘This Way Up’ arrows on the box, ‘Do Not Machine’ labels, or some other way to help speed the process.

Recap & Final Thoughts

Non conveyable items are similar to the end pieces on a loaf of bread; useful, and even necessary, but often we’re just not quite sure what to do with them. But there’s no doubt about it, “winging it” is not a great strategy for handling non-conveyables. Once you have a solid grasp on what’s necessary to handle your irregular items, you can put processes in place and your team will operate much more efficiently.

- First, always determine where automation is possible – in any capacity. Specialized equipment may help you automate handling in ways that your conveyors cannot.

- Second, determine where human interaction is simply unavoidable. Many irregular items require some sort of human assistance to move efficiently through the warehouse.

- Last, consider the transport logistics of your non-conveyables.

Many high volume E-commerce facilities can attest to: there is an art to handling and managing your irregular parcels, but there’s also a “method to the madness.” If you give these items some thought and attention, you can create efficient processes just like the rest of your “regular” items.