Any smooth-flowing system or workflow needs a “director”. The lack of a director, or control system, can lead to utter chaos. Here’s a real-world example.

Taking kids to school or going through downtown traffic can turn into complete anarchy. If there is no cop orchestrating the traffic or no traffic lights directing cars to stop and go, things can get messy very quickly. But when someone or something manages the traffic, far fewer accidents happen.

The same idea applies to your warehouse control system. In order to get peak performance, efficiency, and reliability, someone or something must be the “traffic cop” of your warehouse.

A warehouse control system (WCS) is a software application that directs real-time activities within warehouses and distribution centers. And just like a real traffic cop, a WCS ensures that each of your conveyors, sorters and other pieces of equipment run smoothly, perform with precision, and maximize efficiency to avoid delays.

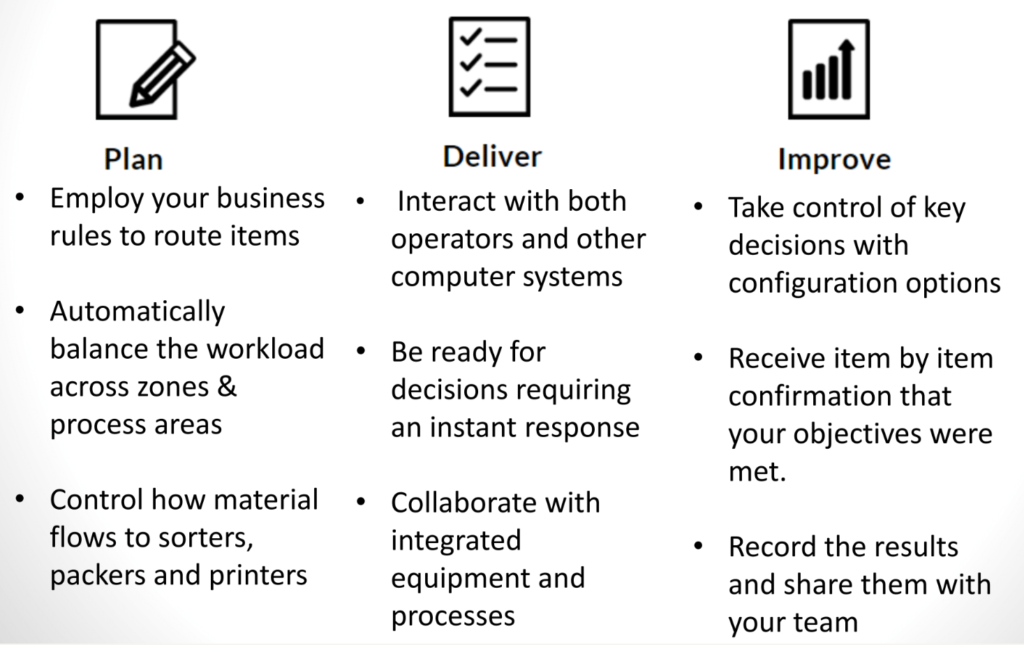

A reliable WCS will ensure that you and your team are better prepared for planning and delivering, and it should also simplify your warehouse, lining everything up under a single point of communication.

Take a look at the image below to see how WCS benefits your warehouse, your team, and your products.

Conveyor Works Services

There are many warehouse control systems out there, but not all of them are made equal. At Lafayette Engineering, we leverage the expertise of top engineers in the country to offer Conveyor Works, a software application designed to integrate and connect all of the moving parts in your warehouse or distribution center.

From a 30,000 ft view, Conveyor Works and any other WCS can help you organize your operations and keep things flowing smoothly. But here are 8 specific ways that Conveyor Works will sync up your warehouse and save you time.

- Batch Picking

- Consolidation -Put to light

- Packing

- Consolidation – Unit Sorter

- Printing Sortation

- Reporting Historical Analysis, Statistics & Productivity

- System Alerts

Batch Picking

- Batches can be separated into single item orders and multiple item orders

- Configurable batch sizes

- Simultaneous picking of batch sizes

- Manage inventory levels and out of stock conditions

- Picking can be accomplished using Pick-to-Light or RF scan guns

Consolidation: Put-to-light

- Fast, high-quality order sortation

- Space efficient & economical

- Locations representing a store or a customer needing a scanned item will illuminate

- Scalable so that the system can grow as you grow

Packing

- Enable users to scan, verify, and close orders

- Automatic detection of duplicate or incorrect items being packed

- Interface with different shipping software providers to:

- Reduce freight costs by rate shopping between carriers

- Eliminate manual shipping processes and reduce errors

- Provide delivery tracking service for your customer

Consolidation – Unit Sorter

- Durable, versatile, and accurate high-speed sortation system

- Sorts a wide range of products safely and gently to the right destination

- Used to sort a large number of individual units to single store orders

- Can be used to fulfill eCommerce or retail store orders

- Items are dropped directly into a chute, allowing for fast packing

Printing Sortation

- Printing of packing slips and invoices

- Printing of carton and shipping labels

- Apply labels to packages as they move along a conveyor

- Verification scanner to ensure that the label was printed and applied properly

Reporting Historical Analysis, Statistics, & Productivity

- The reporting feature allows you to view historical information on operations, increase your visibility to plant floor operations, and reduce your labor requirements and associated costs.

System Alerts:

Monitor real-time status, warnings, and alarms

The Conveyor Works Difference

Many of the integrated material handling systems out there require multiple business systems and dissimilar pieces of equipment to act as “nodes” on a network; communicating and collaborating with each other. However, the exchange of information between these “nodes” can be extremely problematic because many pieces of equipment operate independently, by design. What’s more, some “nodes” don’t even have the decision-making capabilities to respond in the time needed for item-to-item decisions.

Our Conveyor Works warehouse control system is the “middleman”, allowing easier communication between your systems and enabling you to make better real-time decisions. We realize that unique situations create unique problems, and we want to ensure that our solutions actually help you do your job better. If Conveyor Works sounds like a solution that will greatly increase the productivity of your warehouse, give us a call today and speak with a handling solutions expert.