Table of Contents

In the realm of material handling and sortation systems, innovation and efficiency are paramount. The Lafayette Magnetic Sortation LMS system, developed by Lafayette Engineering, Inc. (LEI), stands out as a groundbreaking solution that leverages electromagnetic technology to enhance sortation processes. This blog delves into the intricacies of the LMS system, its design principles, operational advantages, and its potential impact on the industry.

Introduction to Lafayette Engineering, Inc. (LEI)

Lafayette Engineering, Inc. is a prominent player in the engineering and material handling industry, known for its innovative solutions and commitment to quality. The company’s latest offering, the LMS system, underscores its dedication to pushing the boundaries of what’s possible in material handling technology.

The Genesis of the LMS System

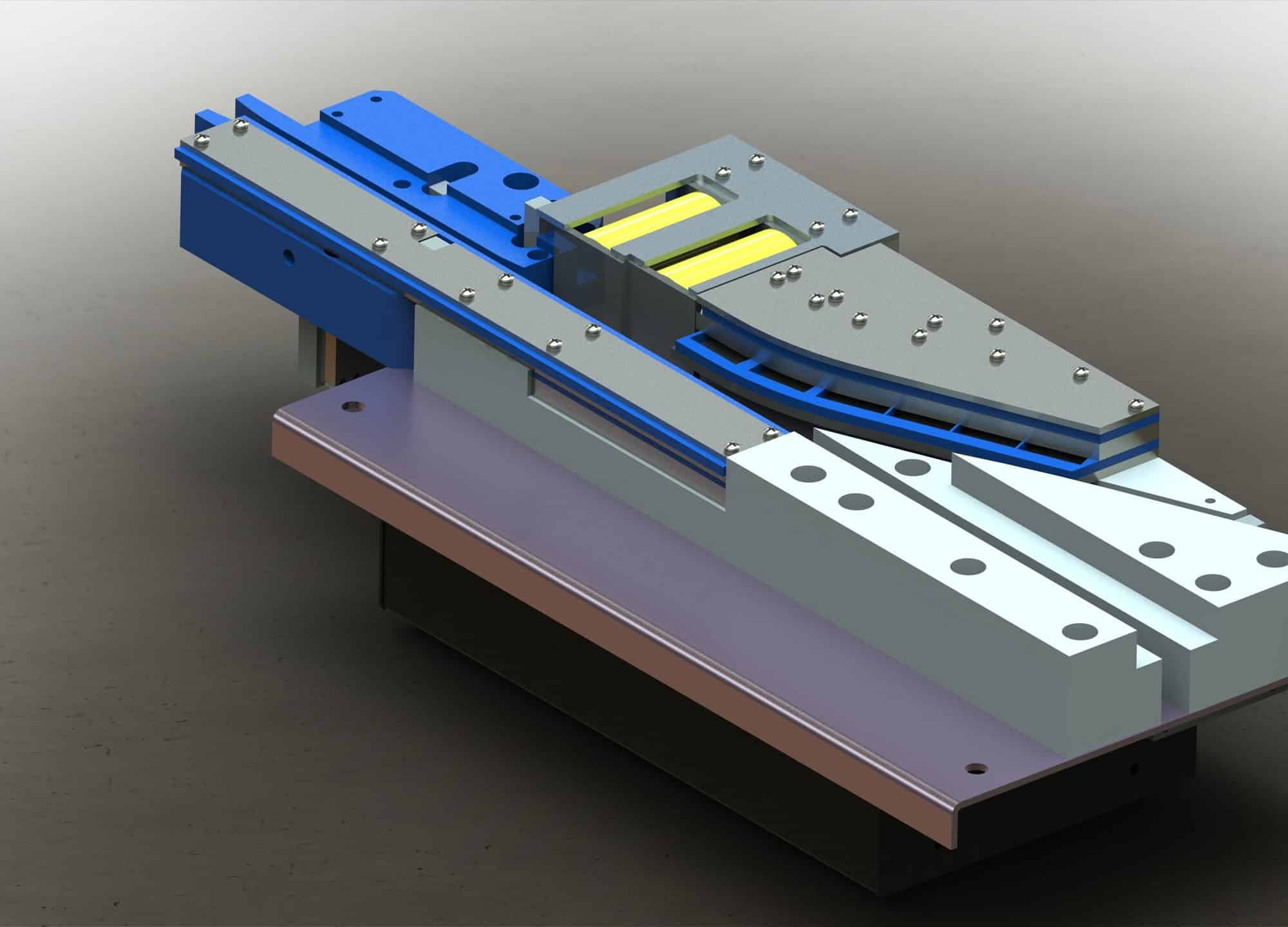

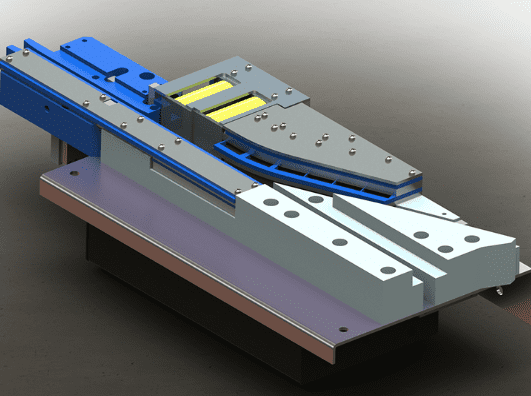

The LMS system is a testament to LEI’s innovative approach to solving common challenges in material handling. Traditional sortation systems often rely on mechanical components that are prone to wear and tear, noise, and require significant maintenance. In contrast, the LMS system uses electromagnetic technology, employing multiple magnets to create magnetic fields that precisely control the movement and sortation of items.

How the LMS System Works

At the heart of the LMS system is its use of electromagnetic technology. The system incorporates multiple magnets within the LMS switch, which generate magnetic fields. These fields are used to attract the pins and/or bearings of shoes towards a diverting path, effectively sorting items without the need for physical contact or mechanical movement. This innovative approach eliminates many of the drawbacks associated with traditional mechanical sortation systems.

Key Features and Benefits

- Speed and Efficiency: The LMS system boasts impressive speed capabilities, reaching up to 725 feet per minute (fpm). This high-speed sortation capability makes it particularly suitable for operations that require rapid processing of items.

- Maintenance and Durability: One of the standout features of the LMS system is its lack of moving components. This design choice significantly reduces the system’s susceptibility to wear and tear, lowers noise levels, and diminishes the need for frequent maintenance.

- Versatility: The LMS system’s design allows for seamless integration into new systems or as a drop-in unit in existing Hytrol sortation systems with minor adjustments. This versatility ensures that businesses can adopt the LMS technology without the need for extensive overhauls of their current infrastructure.

- Innovative Use of Electromagnetic Technology: The application of electromagnetic technology in material handling sortation is a novel approach that sets the LMS system apart from conventional solutions. This technology enables precise and efficient sortation without the mechanical complexities and limitations of traditional systems.

Impact on the Material Handling Industry

The introduction of the LMS system by Lafayette Engineering represents a significant leap forward in sortation technology. Its innovative use of electromagnetic technology not only enhances efficiency and speed but also offers a more sustainable and maintenance-friendly solution. As businesses continue to seek ways to optimize their operations and reduce downtime, the LMS system provides a compelling option that addresses many of the pain points associated with material handling and sortation.

Get In Touch

The Lafayette Magnetic Sortation (LMS) system is a groundbreaking innovation in the field of material handling. With its unique use of electromagnetic technology, high-speed capabilities, and low-maintenance design, the LMS system is poised to revolutionize sortation processes across various industries. Lafayette Engineering’s commitment to innovation and quality is evident in the LMS system, offering businesses a reliable, efficient, and cutting-edge solution to meet their sortation needs.

As the material handling industry continues to evolve, technologies like the LMS system will play a pivotal role in shaping the future of efficient and sustainable operations. The LMS system not only exemplifies Lafayette Engineering’s innovative spirit but also sets a new standard for what is possible in material handling technology.

For more information or inquiries about the LMS system, interested parties can reach out to Lafayette Engineering at inquire@lafayette-engineering.com. This contact point serves as a gateway for businesses to explore how the LMS system can be integrated into their operations, marking the beginning of a new era in material handling and sortation.