Lasting Effects of the Pandemic

Pre-pandemic times were much simpler.

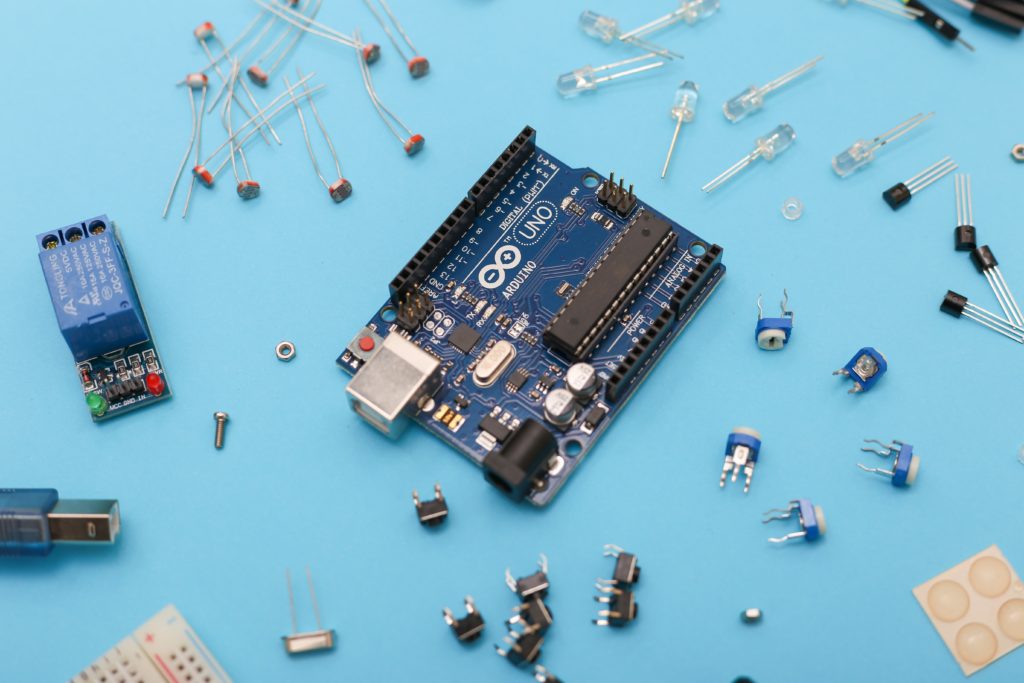

Two years ago, acquiring components and supplies was a simple process. If you needed supplies, you knew where to get them and for the most part, how long it would take to get them.

Supply Acquisition

But things are different in the post-pandemic world. It’s no secret that parts acquisition has become a challenging, and often maddening process.

For example, at LEI we can get about 90% of the material needed for assembling a panel through our typical, tried and true avenues. However, the remaining 10% of panel materials must now be searched for and acquired through non-traditional means.

Lead Time Variability

The supply chain issues brought on by the pandemic have also led to unthinkable lead times.In the post pandemic world, buying online is difficult with unprecedented lead times. This has become our new normal. Suppliers such as Allen Bradley are listing 30-35 weeks wait time for orders on their website, while some individual components are looking upward of 78 weeks. That’s unheard of!

Inventory & Supplier Relationships

There’s nothing worse than being stuck in an ‘out of stock’ situation.

To counteract the long and fluctuating lead times from suppliers, companies began to ‘stock-up’ on inventory as a way to prevent out-of-stock situations from happening during shortages.

It’s crucial to maintain a steady relationship with suppliers and manufacturers during these times. When supply is in high demand, a supplier may allow a certain percentage of its inventory to key customers. This means that other customers may only get a small percentage of what they need for a specific component, resulting in disruptions to their production and a trickle-down effect that extends all the way to consumers.

Opportunity in Unlikely Places

So, what do we do when that isn’t enough? We get creative.

At Lafayette, we’ve turned to “outside the box” methods to keep our operations moving fluidly. Where we were once able to easily find certain parts and supplies, we now have to scour the depths of the internet for!

We’ve learned to get creative; making use of websites like eBay to fill in the gaps when suppliers fall short.

Leveraging Your Inventory

This approach makes spare parts sitting on shelves much more valuable than ever before. Parts that are in your inventory may no longer be required if you’ve upgraded your system, but to others who have not upgraded, those parts are like gold — and they will pay good money for them.

A shortage of inventory naturally adds a significant increase in price. As the old saying goes, “when supply is down, demand goes up.”

A component like the safety input card 1734-IB8S is a perfect example. We normally buy a 1734-IB8S from our supplier for $393.58 (list cost being $648.72). However, these are currently selling new on Ebay from anywhere from $1,500 to over $2,000 each. Due to job demands, we have been forced to buy several of these in order to keep things moving as scheduled.

That’s a 200-300% increase in cost.

And users like us are flocking to buy them because it is the only way to keep our systems functioning within an appropriate timeline. If you have accrued a surplus of parts and supplies for your systems that you no longer need, there is a massive opportunity to turn that surplus into profit.

The same can be said for end-of-life equipment. If there are parts needed for your system that are no longer being manufactured, your best bet is to find an online source who has an excess of those items to sell.

3 Ways Around the Supply Chain Dilemma

Since 2020, LEI has spent over $500k on large surplus orders in an attempt to get ahead of the lead time madness.

That’s one way to do it. But here are a few other ways to get around the supply chain dilemma:

- Substitute the part with a compatible part either from the same manufacturer or a different manufacturer.

- Buy material online from nontraditional sources like Ebay. Although you may have to purchase at a premium cost, it beats not having the part you need.

- Last resort, re-engineer the job. Although not ideal, if you cannot find the backlogged part online or expedite it from your vendor, you may have no other choice.

It’s safe to say that any excess components are an advantageous commodity right now. Many manufacturers and even integrators have begun to list their surplus inventories and are making profits hand over fist. This may be a beneficial route for you as our industry continues to recover from pandemic-driven supply-demand issues.

If you don’t have a team of experts on your side to help you streamline your business, we would love to help you. Call us today at (844) 845-7580.