Table of Contents

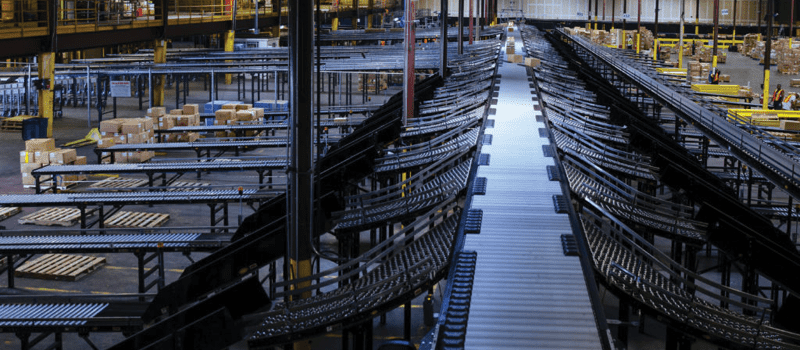

LaFayette Engineering, Inc. (LEI), located in Danville, Kentucky, is a renowned electrical controls company with a specialized focus on Conveyor Systems. They excel in designing and installing control systems specifically for Conveyor Systems, including sophisticated high-speed case sortation. LEI’s services cover a wide array of control engineering solutions, meticulously crafted to support the diverse needs of the material handling and warehouse control sectors.

Overview of Services:

1. Conveyor Systems:

LEI excels in the integration of control systems, particularly for conveyor systems used in material handling. Their approach is comprehensive, starting from the initial design phase to the implementation of these systems in both new and existing facilities. This involves a deep understanding of the client’s needs and the deployment of the latest technology and control devices to enhance system efficiency, reduce operational costs, and increase productivity.

2. Control Panel Design & Fabrication:

They offer specialized services in control panel design and fabrication. This process includes the meticulous design and assembly of control panels that form the nerve center of conveyor systems. LEI’s expertise ensures that these panels are not only functional but also optimized for efficiency and reliability.

3. Warehouse Control Systems:

LEI is also adept at developing warehouse control systems, a critical component for modern warehouses and distribution centers. These systems are designed to streamline operations, improve inventory management, and enhance the overall efficiency of warehouse operations.

View More on Warehouse Control Systems

4. Custom Solutions and Innovative Strategies:

Understanding that each business has unique needs, LEI focuses on providing custom solutions. They research, design, and build innovative systems to solve common and complex material handling problems. This involves close collaboration with clients to understand their specific processes and develop solutions that align with their business goals.

5. Comprehensive Project Process:

LEI’s process encompasses a full range of services from the assessment of client needs to the development and implementation of conveyor concepts. This includes producing detailed AutoCAD electrical control drawings, fabrication of control panels, advanced PLC programming, and project management. They also provide installation coordination, field installation, launch assistance, and ongoing service and support.

6. Commitment to Quality and Integrity:

Under the leadership of Bruce Robbins, the owner, LEI is guided by a commitment to integrity and providing honest solutions. They aim to become a valued business partner for their clients, focusing on delivering high-quality, reliable, and efficient conveyor system solutions.

Conclusion:

LaFayette Engineering’s services are designed to cater to a diverse range of industries requiring sophisticated conveyor systems and control solutions. Their focus on custom solutions, combined with their commitment to quality and integrity, positions them as a valuable partner for businesses seeking to optimize their material handling and warehouse operations.