Table of Contents

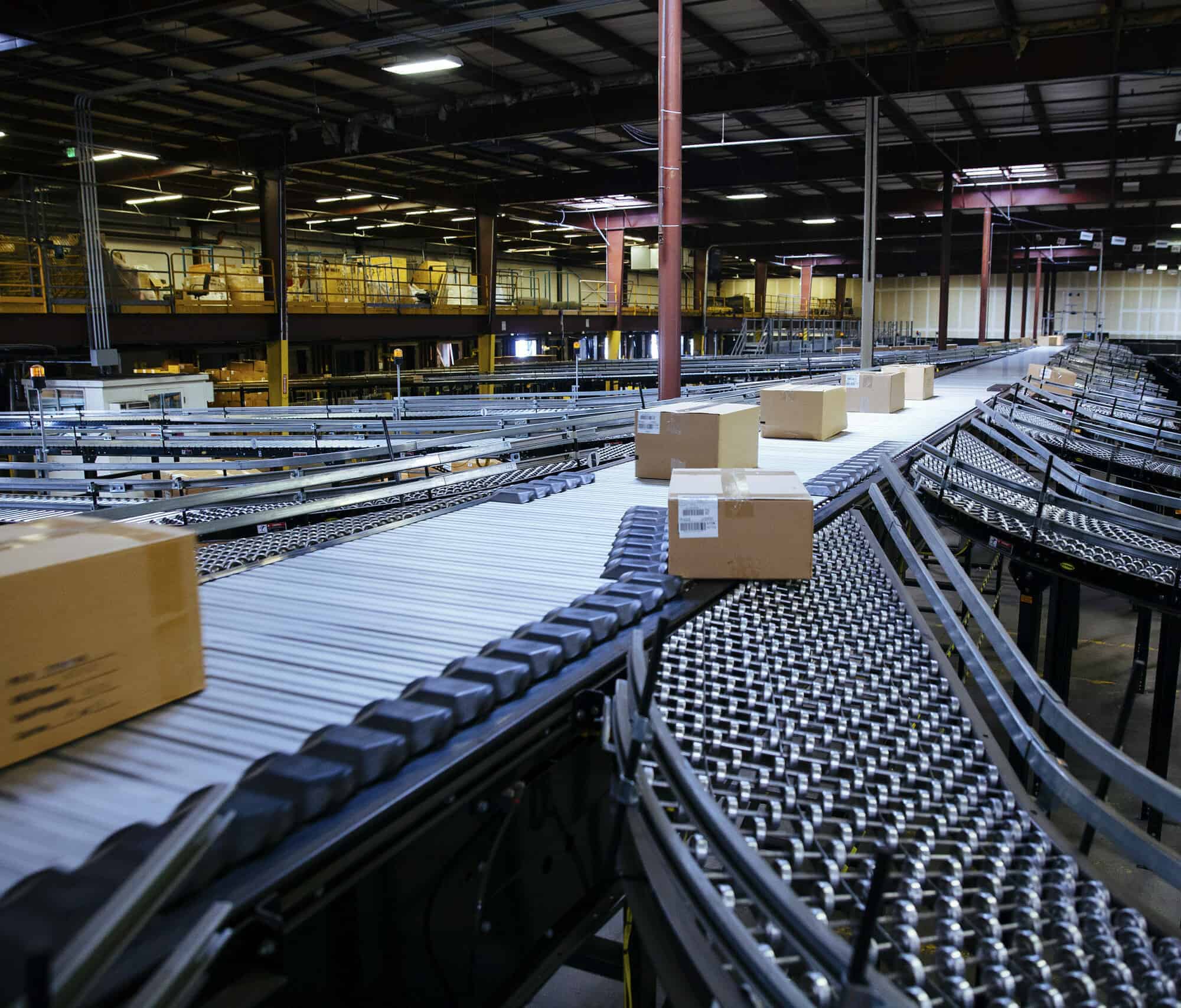

In the dynamic world of warehousing and logistics, efficiency and productivity are paramount. The advent of Automated Sortation Systems has brought about a significant transformation in how warehouse operations are conducted, ensuring that businesses can keep pace with the increasing demands of e-commerce and global distribution.

The Need for Automated Sortation Systems

Traditionally, warehouses managed inventory in bulk, with orders primarily consisting of pallets of goods. However, the rise of online shopping has necessitated a shift towards individual order processing, thereby complicating the sorting, packing, and shipping processes. Automated Sortation Systems have emerged as a solution to this challenge, eliminating the need for manual sorting and significantly enhancing efficiency and labor productivity.

How Automated Sortation Systems Work

Automated Sortation Systems are sophisticated material handling solutions that identify items and direct them to their designated destinations within warehousing and storage facilities. These systems leverage advanced algorithms and codes, often integrating with Warehouse Management Systems (WMS) and Internet of Things (IoT) technologies to optimize operations. By automating the sorting process, these systems reduce the reliance on manual labor, thereby minimizing errors and increasing throughput.

Benefits of Implementing Automated Sortation Systems

- Increased Productivity and Efficiency: By automating repetitive tasks, sortation systems allow warehouse workers to focus on more value-added activities, thereby increasing overall productivity and efficiency.

- Enhanced Accuracy: Automated systems minimize human errors, ensuring that orders are processed correctly, which in turn enhances customer satisfaction and business reputation.

- Reduced Labor Costs: Automating the sortation process reduces the need for manual labor, helping businesses to manage labor costs more effectively, especially in high-volume operations.

- Improved Workplace Safety: Automated systems reduce the physical and mental strain on workers, lowering the risk of workplace accidents and promoting a safer working environment.

- Scalability and Flexibility: Automated Sortation Systems can be scaled and adapted to meet changing business needs, making them a versatile solution for warehouses and distribution centers of all sizes.

Industries Benefiting from Automated Sortation

Automated Sortation Systems find application across various industries, including automotive, e-commerce, pharmaceuticals, and food and beverage. These systems are particularly beneficial in sectors where high-volume material handling is a critical component of operations.

The Future of Automated Sortation

The global market for Automated Sortation Systems is on a growth trajectory, with projections indicating a significant increase in market size in the coming years. This growth is driven by the continuous evolution of e-commerce and the increasing need for efficient warehousing solutions. As technology advances, the capabilities of sortation systems are expected to expand, further enhancing their efficiency and effectiveness.

Automated Sortation Systems Recap

Automated Sortation Systems represent a significant leap forward in warehousing and logistics operations. By streamlining the sorting process, these systems not only improve operational efficiency but also contribute to better workplace safety and customer satisfaction. As businesses continue to navigate the complexities of global distribution and e-commerce, the adoption of automated sortation solutions is set to become a standard practice, driving the future of warehousing towards greater innovation and efficiency.

LaFayette Engineering Role in Automated Sortation Systems

Lafayette Engineering, a prominent player in the field of material handling and automation, plays a pivotal role in the integration and implementation of Automatic Sortation Systems within the logistics and warehousing industry. As businesses increasingly seek efficient, reliable, and scalable solutions to meet the growing demands of e-commerce and global distribution, Lafayette Engineering stands out as a key facilitator in optimizing warehouse operations through advanced sortation technology.

Automatic Sortation Systems are at the heart of modern warehousing, designed to expedite the process of sorting goods based on destination, size, weight, or other predefined criteria. These systems are crucial for distribution centers, e-commerce fulfillment, manufacturing plants, and postal services, where high-volume and accurate sorting operations are essential for efficiency and customer satisfaction. Lafayette Engineering’s expertise in this domain ensures that businesses can leverage the full potential of automated sortation to enhance their operational throughput and accuracy.

Lafayette Engineering’s approach to integrating Automatic Sortation Systems is comprehensive, encompassing consultation, design, installation, and maintenance. The company’s team of experts works closely with clients to understand their specific needs, challenges, and objectives. This client-centric approach ensures that each sortation solution is tailored to the unique requirements of the business, whether it’s improving throughput, reducing errors, or enhancing overall efficiency.

One of the key strengths of Lafayette Engineering is its ability to provide end-to-end solutions. From the initial assessment of a facility’s layout and operational flow to the selection of appropriate sortation technology and its integration with existing Warehouse Management Systems (WMS), Lafayette Engineering ensures a seamless transition to automated sortation. This holistic approach minimizes disruptions to ongoing operations and maximizes the return on investment for businesses looking to modernize their warehousing and distribution operations.

Lafayette Engineering’s role in the implementation of Automatic Sortation Systems also extends to training and support. Understanding that the success of any automation project relies not only on the technology but also on the people operating it, Lafayette provides comprehensive training to ensure that staff are proficient in using the new systems. Ongoing support and maintenance services further ensure that the sortation systems operate at peak efficiency, with minimal downtime and maximum productivity.

The impact of Lafayette Engineering’s work in the field of Automatic Sortation Systems is significant. By enabling faster, more accurate sorting processes, Lafayette helps businesses to meet the ever-increasing expectations of their customers for quick and reliable delivery. This is particularly crucial in the e-commerce sector, where the ability to efficiently process a high volume of orders can be a competitive advantage.

Moreover, Lafayette Engineering’s solutions contribute to a safer and more ergonomic working environment. Automated sortation systems reduce the need for manual handling of goods, thereby lowering the risk of workplace injuries and enhancing employee satisfaction. This not only supports a healthier workforce but also aligns with broader industry trends towards more sustainable and responsible operational practices.

In conclusion, Lafayette Engineering’s role in the realm of Automatic Sortation Systems is transformative. By harnessing the power of automation, Lafayette not only enhances the operational capabilities of businesses but also drives innovation in the logistics and warehousing industry. As the demand for efficient, accurate, and scalable sorting solutions continues to grow, Lafayette Engineering’s expertise and comprehensive solutions position it as a leader in helping businesses navigate the complexities of modern warehousing and distribution.