Table of Contents

At Lafayette Engineering, we are often asked, “What is control systems engineering?” This question is fundamental to understanding our field and the exciting, critical work we do. Control systems engineering is a multidisciplinary field that combines elements of electrical engineering, mechanical concepting and design, computer science, and mathematics to design and manage systems that behave in a desired manner. From maintaining the temperature in a building to stabilizing aircraft flight, control systems engineering plays a critical role in numerous applications.

1. Fundamental Understanding of Dynamic Systems

What is control systems engineering if not the mastery of dynamic systems? These are systems that change over time and are affected by various inputs. Control engineers at Lafayette Engineering develop mathematical models to represent these systems, which can range from simple household appliances to complex industrial processes. This fundamental understanding allows our engineers to predict system behavior and design controls to achieve desired outcomes.

2. Design and Implementation of Controllers

One of the primary tasks in understanding what is control systems engineering involves designing and implementing controllers. Controllers are algorithms or devices that adjust system inputs based on feedback to achieve a desired output. By designing effective controllers, we ensure systems operate efficiently, safely, and reliably.

3. What is Control Systems Engineering? Explore Its Wide Range of Applications

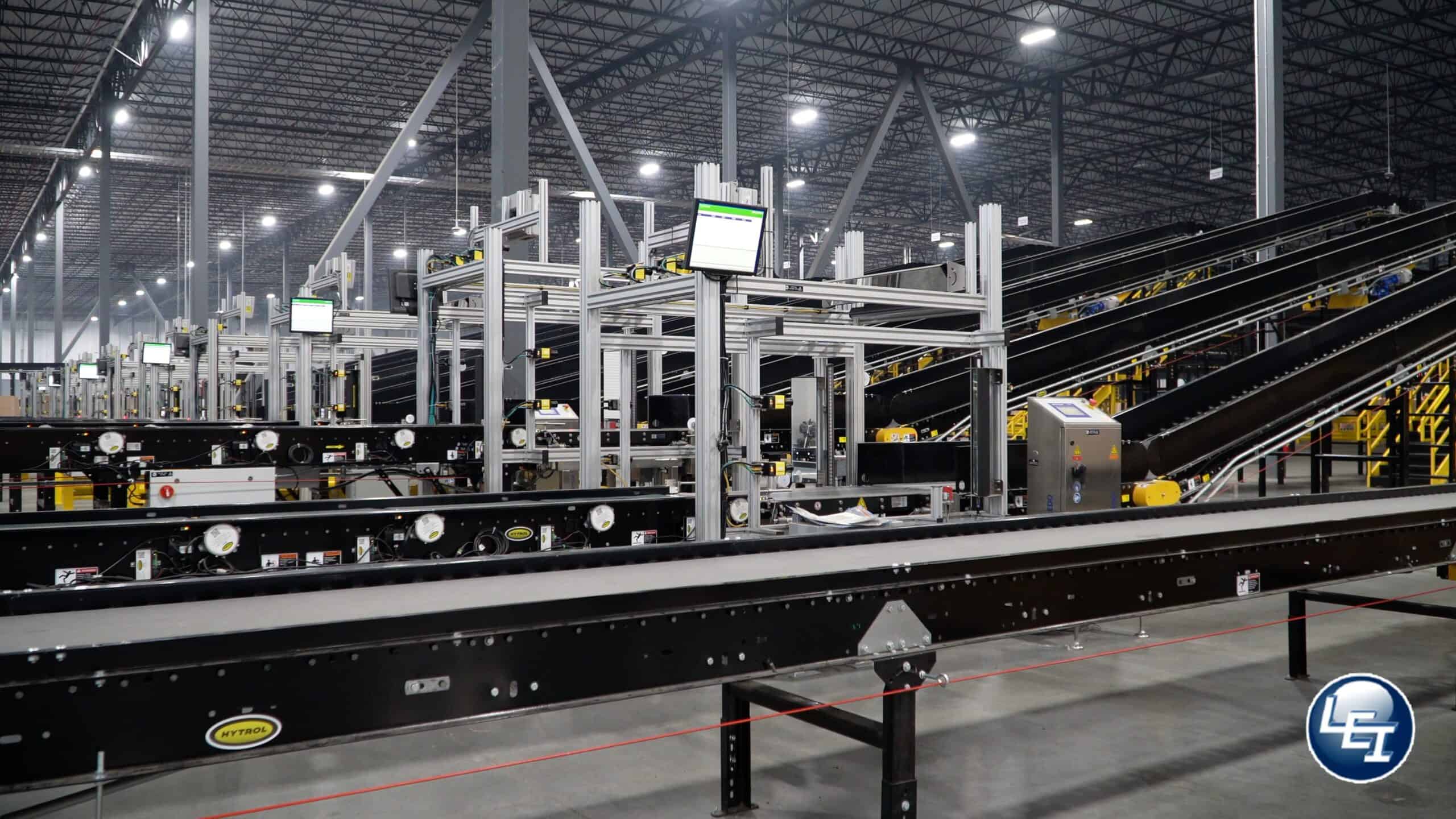

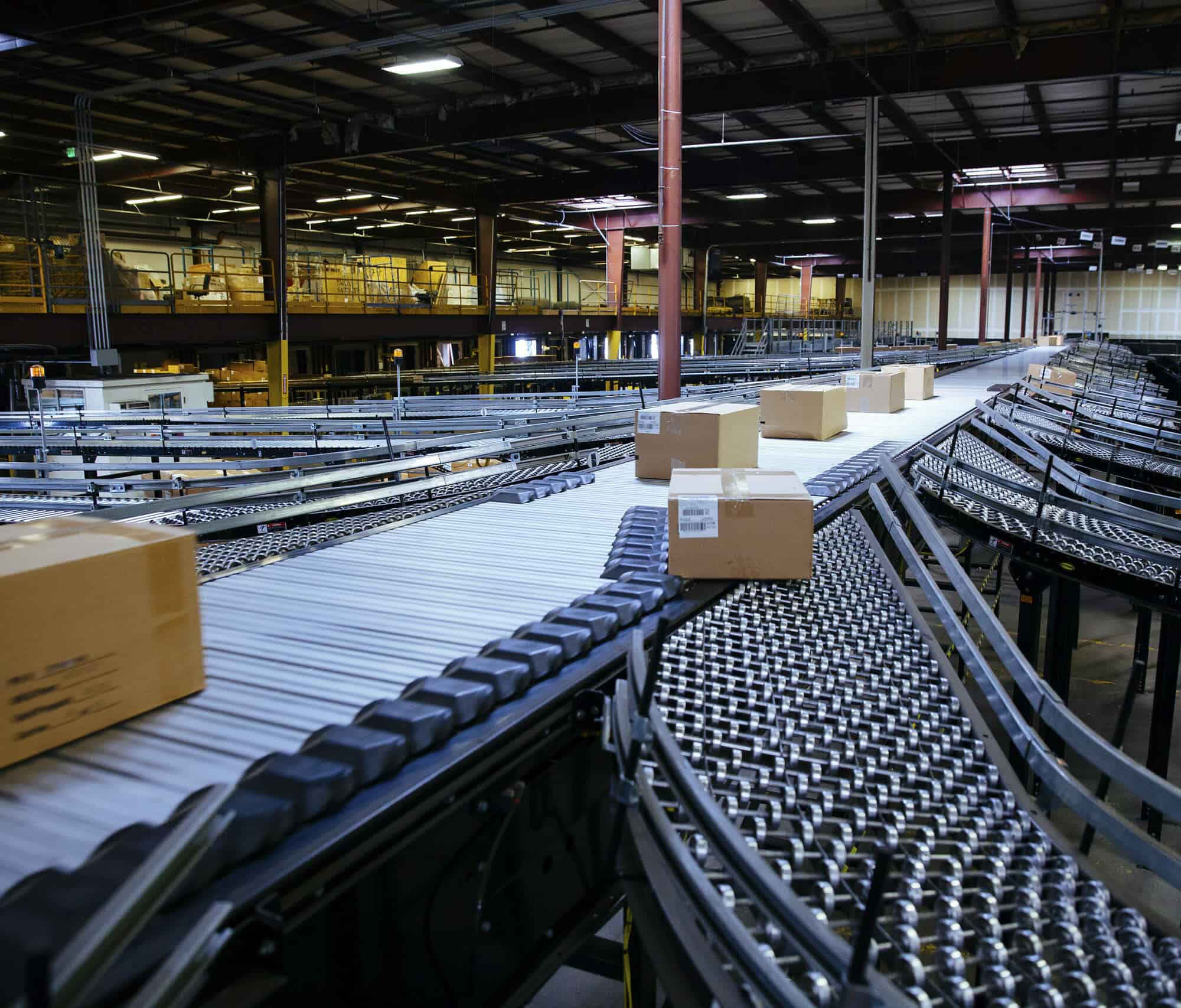

When exploring what is control systems engineering, it’s essential to recognize its broad spectrum of applications across various fields. In the automotive industry, control systems are used for engine management, cruise control, and autonomous driving. In manufacturing, they ensure the precision and efficiency of production lines.

4. Integration of Cutting-Edge Technologies

Another critical aspect of understanding control systems engineering is recognizing its role in integrating cutting-edge technologies. This includes the use of artificial intelligence (AI) and machine learning (ML) to develop smarter and more adaptive control systems. For example, AI can be used to optimize traffic control systems in real-time or enhance the capabilities of robotic systems. At Lafayette Engineering, the integration of such technologies not only improves system performance but also opens new possibilities for innovation.

5. Balancing Theory and Practical Application

What is control systems engineering if not a perfect balance between theoretical knowledge and practical application? Engineers must have a strong foundation in mathematics and physics to develop accurate models and understand system dynamics. At the same time, they need practical skills to implement and test control strategies in real-world scenarios. At Lafayette Engineering, this combination of theory and practice makes the field both challenging and rewarding.

6. Problem-Solving and Innovation

When asked what is control systems engineering, we emphasize its core focus on solving complex problems. Engineers in this field are constantly faced with challenges that require innovative solutions. No matter the control system challenge, engineers at Lafayette Engineering must think creatively and apply their knowledge to develop effective solutions. This problem-solving aspect makes the field dynamic and exciting.

7. Impact on Modern Society

Understanding control systems engineering reveals its profound impact on modern society. Many of the conveniences and technologies we rely on daily are made possible by control systems. From the smooth operation of public transportation systems to the precise control of medical equipment, control systems engineering enhances our quality of life and drives technological progress. Engineers at Lafayette Engineering contribute to the development of safer, more efficient, and more reliable systems that benefit society as a whole.

Summary of Control Systems Engineering

So, what is control systems engineering? It is a fascinating and essential field that combines theoretical knowledge with practical applications to solve complex problems. It has a wide range of applications across various industries, integrates cutting-edge technologies, and significantly impacts modern society. At Lafayette Engineering, we are proud to be at the forefront of this dynamic field. For those with a passion for innovation and problem-solving, control systems engineering offers a challenging and rewarding career path. Understanding control systems engineering provides insight into the crucial role this field plays in shaping our technological landscape and improving our everyday lives.

Follow Lafayette Engineering on LinkedIn!